|

|   |

Overview

The Manage Ideal Times form is used to define the ideal Setup, Cycle Time and Operation Time (PPH) for equipment / part number combinations. Ideal Times, sometimes referred to as Standard Time, is the planned amount of time to do something.

Default ideal setup time the default ideal cycle time and default Operation Time (PPH) can optionally be define so that you are able set defaults at the equipment and part levels. This is done so that you can get up and running quickly with ideal setup and cycle times as well as quality percentages without having to specify the ideal times for all equipment / part combinations.

Ideal times for setup and cycle time have the ability to be specified on an Equipment / part number basis. This is the more accurate way do to it, but requires ongoing maintenance to keep the information filled out as new parts or equipment are added to the system. If you have specified a value at the equipment / part level, those values will override the defaults.

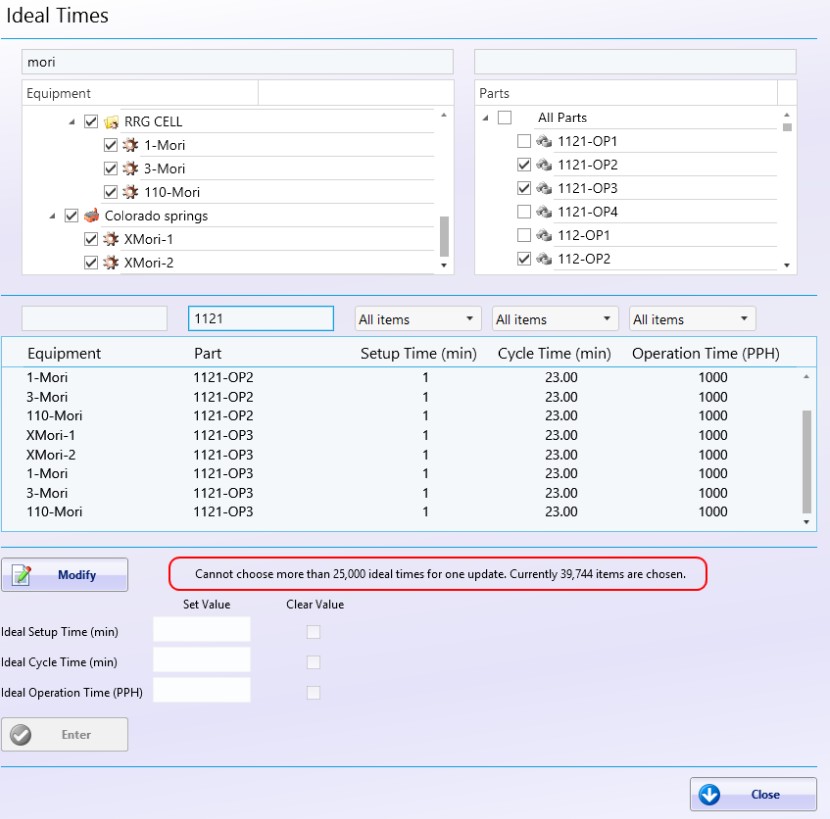

You can update the values of large groups of parts and of equipment with a ‘mass’ update ability. By using that feature, you will not need to update each item individually. To do this, the use the tree with checkboxes. The Equipment hierarchy consist of the Plant, Group, equipment structure. Part Numbers will use a tree as well as checkboxes but the hierarchy consist of a Part Group, Plant, Part Group, Part Number structure. Keep in mind that it is only possible to update 25000 records or less through the user interface. If more than 25000 records need to be updated please use the ideal time import option. More information can be found here.

Screen Layout

The Ideal Values screen is broken down into three main parts. The top area is where the part and equipment combination can be selected. The area in the middle, or 'grid' displays the current value for that part and equipment combination that have been selected from above. The bottom area is where values are entered. See the image below for more details.

You can use the filter boxes above the Equipment and Part columns as well as the drop downs above Setup Time and Cycle Time columns to further filter down a large selection of parts and equipment. Blue Values that are offset over to the right are inherited from a default value. Defaults can be inherited from the the default forms as described above. In this case the blue values can be changed for Ideal setup, cycle time and Operation time by selecting an equipment and part combination and modifying the set values.

Use the Set Value to enter the cycle time, Quality Percentage and operation time.

Use the Clear Value option to clear any values set for part / equipment combination. Note, if there is a default value set, it will then inherit that value.

Entering Default Ideal Values

Find the equipment and part combination that you would like to add or modify the ideal setup or cycle time and check the boxes. After the equipment and part combination are checked, click the modify button. Set the value for the Setup and Cycle Time and click the Enter button. You can then move on to the next equipment / part combination that you would like to set the next values for.

Through the User Interface, it is only possible to update up 25000 ideal time records. If more than 25000 records need to be updated please use the ideal time import option. More information can be found here.